AI in Manufacturing: 8 Game-Changing Use Cases in 2025

Riten Debnath

05 Oct, 2025

Artificial Intelligence (AI) is transforming manufacturing in 2025 by making factories more intelligent, efficient, and agile. AI enables better decision-making, reduces costs, and improves product quality throughout the manufacturing process. From predicting equipment failures to optimizing supply chains, AI is reshaping how factories operate worldwide.

I’m Riten, founder of Fueler, a platform that helps freelancers and professionals get hired through their work samples. This article explores eight impactful AI use cases in manufacturing today. Remember, having technical skills is essential, but showcasing your work effectively is what sets you apart. A well-crafted portfolio proves your expertise and builds trust with employers and clients.

1. Predictive Maintenance: Stop Failures Before They Happen

Traditional maintenance schedules often lead to unnecessary repairs or unexpected breakdowns. Predictive maintenance uses AI to continuously analyze data from machines, such as vibrations, temperature, and sound, to forecast potential failures days or weeks in advance.

- IoT sensors monitor machine performance 24/7

- AI detects abnormal patterns indicating wear or failure

- Platforms like IBM Maximo provide AI-based asset health monitoring

- Augury uses sound analytics and machine learning for fault detection

- Siemens’ Mindsphere collects and analyzes operational data from connected devices

Why it Matters: Avoiding sudden breakdowns saves manufacturers money by reducing production stoppages and lowering maintenance costs. Predictive maintenance increases equipment lifespan and keeps factory operations running smoothly in 2025.

2. AI-Driven Quality Control: Detect Defects with Precision

Manual inspections often miss subtle defects and slow down production. AI-powered vision systems automate inspections by scanning every product on the line in real time, identifying flaws like scratches, color variations, or assembly errors.

- Uses high-resolution cameras combined with AI for deep analysis

- Real-time defect detection improves accuracy and speed

- Landing AI offers customizable visual inspection solutions

- Instrumental identifies defect patterns and root causes automatically

- Covision enhances yield by maintaining consistent quality

Why it Matters: AI-driven quality control minimizes waste and defective products, protecting brand reputation while saving costs associated with rework and returns in 2025.

3. Supply Chain Optimization: Smarter Planning and Risk Management

Managing a supply chain involves complex logistics with tight deadlines. AI analyzes historical sales, market trends, and external factors like weather to forecast demand and assess supplier risks.

- Predicts customer demand to avoid overstocking or shortages

- Monitors supplier reliability and flags potential disruptions

- Llamasoft simulates supply chain scenarios for better decision-making

- SAP AI integrates supply chain data with AI insights for visibility

- Blue Yonder uses machine learning to optimize inventory and fulfillment

Why it Matters: AI-powered supply chain optimization helps manufacturers deliver products faster, reduce costs, and quickly respond to changes, maintaining high operational efficiency in 2025.

4. Generative AI in Product Design: Innovate Faster

Designing new products can be time-consuming and expensive. Generative AI automates the design process by creating thousands of design variations based on set constraints, helping engineers find innovative, cost-effective solutions.

- AI generates multiple 3D model options automatically

- Supports rapid prototyping and testing of design concepts

- Tools like Autodesk Generative Design accelerate creativity

- Siemens NX integrates AI within computer-aided design (CAD) workflows

- nTopology optimizes material usage for lightweight and strong parts

Why it Matters: Generative AI shortens design cycles and reduces material waste, enabling manufacturers to launch innovative products quickly while cutting costs in 2025.

5. Energy Efficiency Optimization: Save Costs and Go Green

Manufacturing plants consume huge amounts of energy. AI analyzes usage patterns and dynamically controls machinery to reduce energy waste and lower utility bills while supporting sustainability. In this context, industrial AI plays a crucial role in optimizing operations and ensuring efficient energy management.

- Tracks energy use across production equipment in real time

- Predicts consumption spikes and adjusts power distribution

- Platforms like Innowatts forecast energy demand for optimization

- Grid Edge AI automates energy savings through smart controls

- Shuts down idle or inefficient equipment automatically

Why it Matters: Reducing energy waste not only lowers costs but also helps manufacturers meet environmental regulations and sustainability goals in 2025.

6. Autonomous Robots: Safer, Faster Assembly

AI-controlled robots perform repetitive or hazardous tasks with precision and flexibility. Collaborative robots (cobots) safely work alongside humans, adapting to changes in production lines.

- Cobots assist with assembly, packaging, and quality checks

- AI enables robots to learn and adjust in real time

- Leading systems include FANUC, KUKA, and ABB Robotics

- Robots increase speed and reduce human errors

Why it Matters: Automation with AI-driven robots raises production efficiency while improving workplace safety and quality assurance in 2025.

7. Demand Forecasting and Inventory Management: Stay Stocked Smartly

AI models analyze historical sales and external influences to predict future demand accurately. This helps maintain the optimal inventory, preventing costly overstock or shortages.

- Combines multiple data sources for precise forecasting

- Automates reorder alerts and stock tracking

- Tools like MachineMetrics and Kinaxis RapidResponse streamline inventory

- Integrates with ERP systems for smooth operations

Why it Matters: Accurate demand prediction and inventory management improve cash flow and ensure timely delivery of products in competitive 2025 markets.

8. AI-Enhanced Worker Safety and Training: Protect and Prepare

AI monitors factory environments and worker actions to detect safety risks. It also powers virtual and augmented reality training that gives workers hands-on experience in a safe, controlled setting.

- Cameras and sensors track unsafe behaviors or hazardous conditions

- AI alerts supervisors to potential accidents in real time

- AR/VR platforms provide interactive training scenarios

- Tools like Smartvid.io analyze safety footage to identify risks

Why it Matters: Improving worker safety reduces accidents and associated costs, while advanced AI training enhances skill development and compliance with safety standards in 2025.

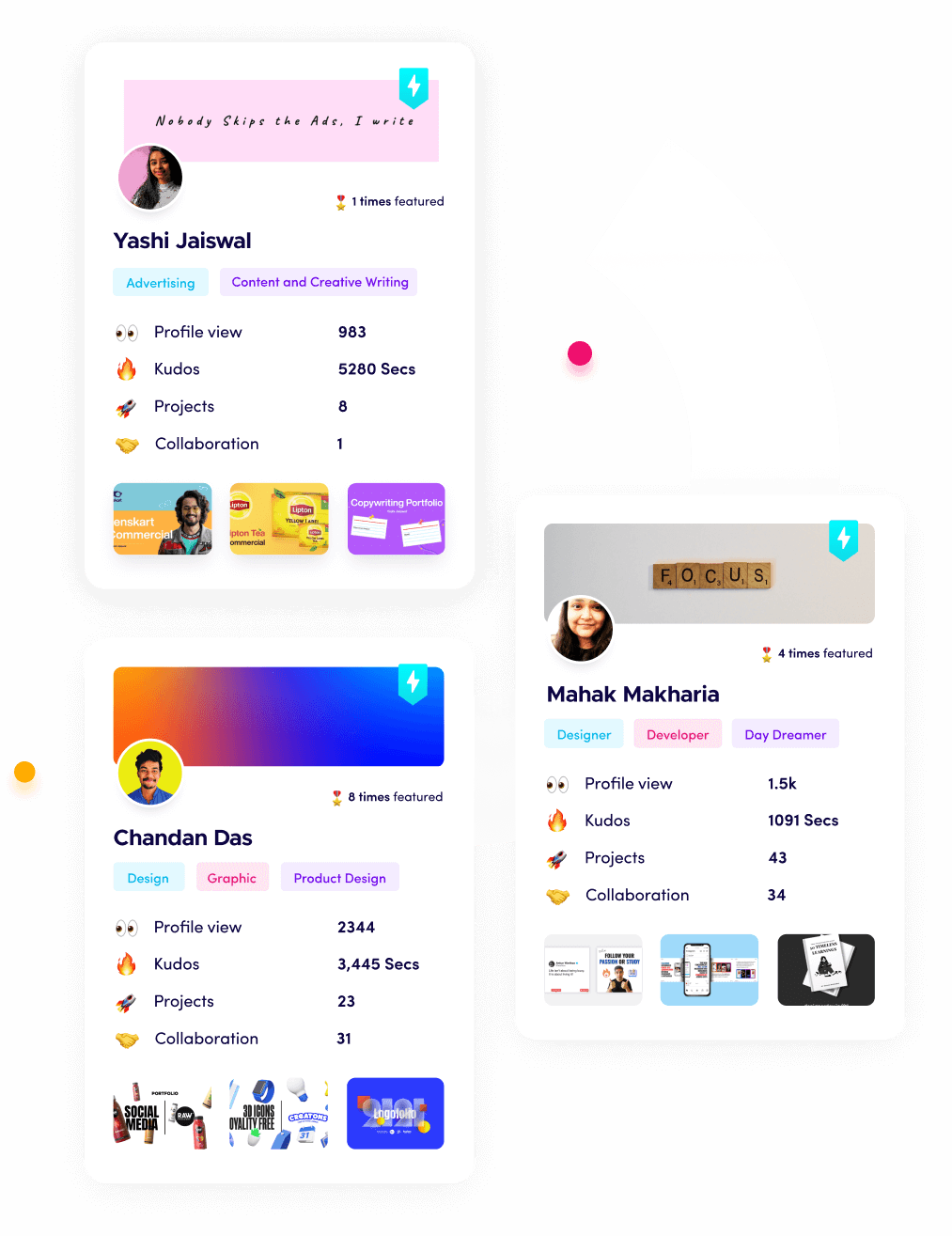

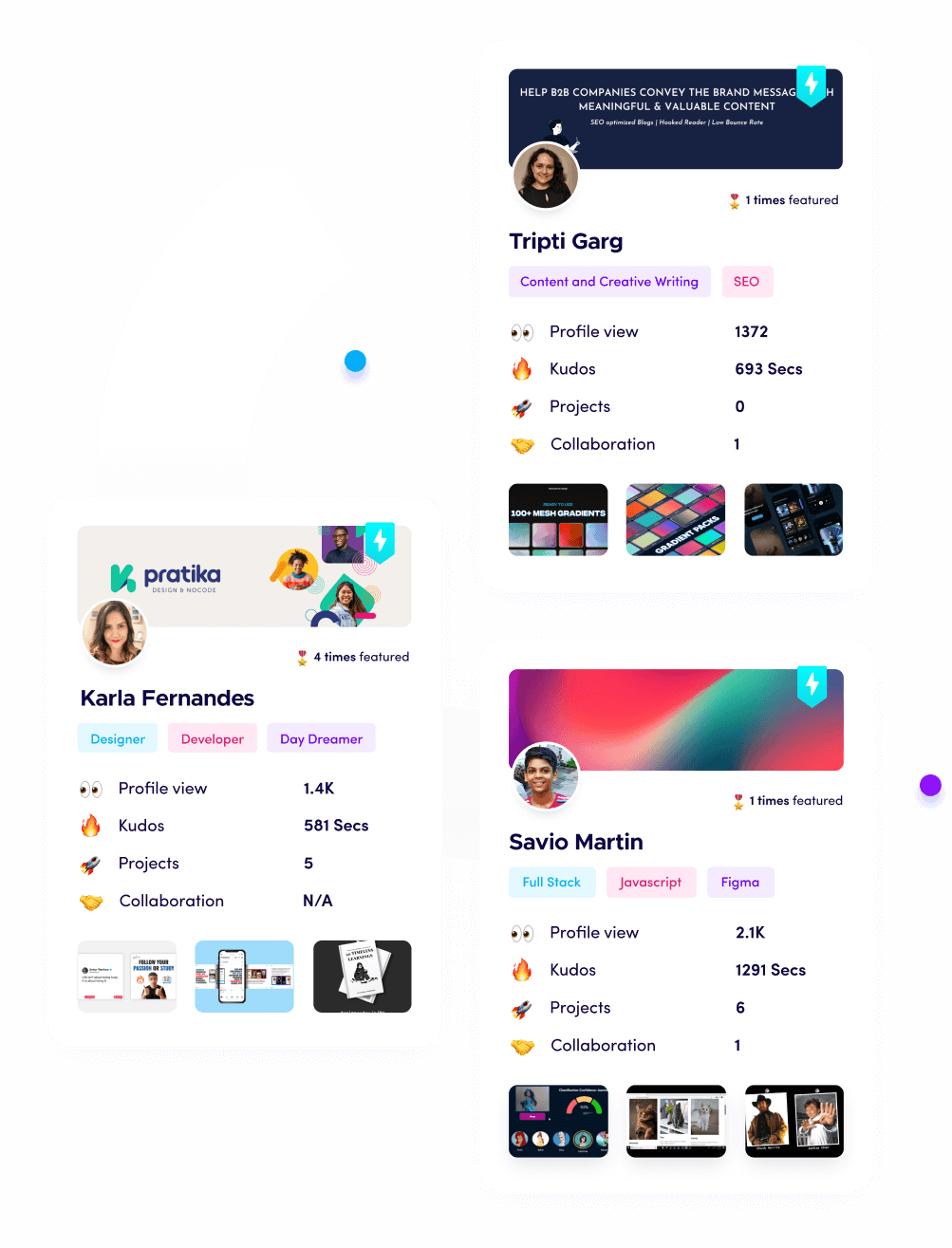

How Fueler Helps Showcase Your AI Manufacturing Skills

In today’s competitive market, simply having the skills isn’t enough. Platforms like Fueler help freelancers and professionals create portfolios that showcase their AI projects and practical experience clearly. Demonstrating your problem-solving with real work samples proves your value to employers and clients. In 2025, a strong portfolio on Fueler could be your key to landing exciting AI manufacturing jobs.

Final Thoughts

AI is reshaping manufacturing in every aspect production, quality, supply chains, safety, and more. These eight use cases highlight how AI enables smarter, faster, and more sustainable manufacturing in 2025. Embracing these advances and effectively presenting your expertise can help you stay ahead in this evolving industry.

FAQs

1. What are the best free AI tools for manufacturing in 2025?

Some popular free or trial AI tools in manufacturing include IBM Maximo for equipment maintenance management, Landing AI for defect detection through computer vision, and Siemens Mindsphere for connecting IoT devices and analytics. These tools allow manufacturers to explore AI benefits without major upfront costs.

2. How does AI improve supply chain management in manufacturing?

AI helps by accurately forecasting demand, monitoring supplier risks, and optimizing inventory. This reduces delays, lowers storage costs, and makes supply chains more agile and reliable, allowing manufacturers to meet customer orders on time.

3. What is predictive maintenance and why is it important?

Predictive maintenance uses AI to monitor machine condition and predict failures early. This prevents unexpected breakdowns, reduces downtime, saves repair costs, and helps factories run efficiently without sudden interruptions.

4. How can AI-driven quality control reduce manufacturing costs?

AI automates product inspection using cameras and sensors to find defects early. This reduces waste, recalls, rework, and increases customer satisfaction by delivering consistent, high-quality products.

5. How can I showcase my AI manufacturing projects to get hired?

Create a detailed portfolio with examples of your AI projects, including tools used, problems solved, and results achieved. Platforms like Fueler help you organize and

What is Fueler Portfolio?

Fueler is a career portfolio platform that helps companies find the best talent for their organization based on their proof of work. You can create your portfolio on Fueler, thousands of freelancers around the world use Fueler to create their professional-looking portfolios and become financially independent. Discover inspiration for your portfolio

Sign up for free on Fueler or get in touch to learn more.