AI in Supply Chain: How US Companies Are Reducing Costs

Riten Debnath

25 Nov, 2025

Global supply chains are going through one of the most uncertain times in history. With rising fuel prices, volatile demand patterns, shipping delays, and increased labour shortages, companies in the United States are under immense pressure to operate efficiently while keeping costs low. This is where Artificial Intelligence (AI) has emerged as a game-changer. By automating manual processes, forecasting future demand, and optimizing logistics, AI is helping companies reduce waste, lower overheads, and achieve better cost control.

I’m Riten, founder of Fueler, a platform that helps freelancers and professionals get hired through their work samples. In this article, I’ll walk you through how US businesses are using AI in their supply chains to cut costs, which tools are leading this transformation, and why learning how to showcase such work in your professional portfolio can set you apart. Your portfolio is not just a collection of work, it’s your evidence of ability, your credibility, and your shortcut to building trust with clients or employers.

AI in Supply Chain Management: An Overview

Artificial Intelligence in supply chains is not limited to automation. It involves the use of machine learning, natural language processing, robotics, and predictive analytics that allow companies to make better, data-driven decisions in real-time. This not only reduces human error but also helps organizations stay agile in a fast-changing global economy.

Key ways AI impacts supply chains

- Demand forecasting becomes more accurate since AI models analyze massive data sets including past sales, seasonal trends, economic indicators, and even weather patterns. This allows companies to avoid situations of overproduction which ties up capital, or underproduction which results in stockouts and lost sales.

- Predictive maintenance reduces downtime by monitoring equipment health through sensors and alerting managers about failures before they happen. For manufacturers, this translates to saving thousands of dollars in lost productivity and emergency repairs.

- Route optimization cuts delivery costs as AI-powered systems calculate the fastest and most fuel-efficient delivery routes, taking into account variables like traffic, accidents, or weather disruptions. Delivery fleets often reduce fuel costs by 10–20 percent on top of the savings that the best fuel credit cards provide, while improving customer satisfaction.

- Automated quality checks lower waste as AI-powered computer vision systems inspect products in real time during production. This reduces defective products, avoids expensive recalls, and ensures customers receive consistent quality.

- Inventory optimization ensures capital efficiency by balancing supply with demand across multiple regions. Instead of piling up products in warehouses, AI keeps inventory lean, minimizing storage costs while avoiding shortages.

Why it matters: In a landscape where every dollar saved impacts profitability, AI-powered supply chains help US companies cut hidden costs, improve decision-making, and remain more resilient to global shocks like supply disruptions or inflation.

AI-Powered Demand Forecasting Tools

Accurate demand forecasting is one of the most powerful applications of AI in the supply chain. Unlike traditional forecasting, which depends heavily on historical averages, AI blends real-time sales, external market data, and advanced learning models to predict trends more precisely. For retail chains, consumer goods companies, and manufacturers, this can directly determine whether they lose money or stay ahead of customer expectations.

Leading AI demand forecasting tools

- Blue Yonder: A leading AI-driven supply chain tool that provides deep insights into sales demand across multiple channels. It takes into account customer behavior across online and offline platforms, helping retailers adjust production and distribution in near real-time. This reduces the cost of excess inventory and prevents stock-outs during peak seasons.

- o9 Solutions: Known for its scenario-planning capabilities, o9 offers a "digital brain" for businesses to perform what-if analyses. Companies can plan for sudden shocks such as raw material price increases or labor shortages, and see the financial impact before making a decision. It's especially useful for large enterprises managing global networks.

- Forecast Pro: A practical tool for mid-sized companies that need reliable forecasting without the complexity of enterprise systems. It combines statistical algorithms with easy integration into existing ERP systems, making it suitable for supply chain managers who need accuracy but also simplicity in use.

- Amazon Forecast: Built on AWS, it uses advanced machine learning to provide scalable, highly customizable demand forecasts. Since it integrates easily with Amazon Web Services infrastructure, companies can use it for everything from predicting product demand to planning workforce schedules.

Pricing

- Blue Yonder: Enterprise-only, custom quotes based on supply chain size.

- o9 Solutions: Tailored pricing model for large corporations.

- Forecast Pro: Starts at around $5,000 per license for mid-size operations.

- Amazon Forecast: Pay-as-you-go model, starting as low as $0.60 per 1,000 data points processed.

Why it matters: Demand prediction is central to cost-saving. Every miscalculation either blocks capital in storage or risks lost revenue due to shortages. AI-based demand forecasting allows US companies to find the sweet spot, ensuring they meet customer needs without overspending on inventory.

AI for Warehouse Automation

Warehousing is often one of the most expensive areas of supply chain management, consuming costs in labor, errors, and delays. AI integration in warehouses brings robotics, computer vision, and autonomous systems together to streamline essential operations like sorting, packaging, and transporting goods.

How AI optimizes warehouses

- Autonomous mobile robots (AMRs) reduce labor dependency by transporting goods independently within facilities. They navigate seamlessly around workers and shelves, speeding up tasks without requiring costly and repetitive human effort.

- AI-powered pick-and-pack systems increase efficiency by learning from order histories and patterns. These systems can suggest the best way to group items for faster processing and minimize errors during order fulfillment.

- Computer vision ensures quality and accuracy by scanning barcodes, checking item damage, and tracking real-time inventory at lightning speed. This cuts down on costly mistakes such as shipping wrong or defective items.

- Dynamic warehouse layouts improve productivity as AI constantly analyzes which items are in the highest demand and reorganizes storage patterns to minimize employee travel time. It results in better use of space and quicker order completion.

- Safety monitoring reduces accidents by using AI to analyze patterns of movement, identify risks, and alert staff about hazards in the warehouse, which prevents costly worker injuries and downtime.

Why it matters: Labor shortages and wage hikes have put added pressure on warehouse operating costs in the US. AI-driven automation is not just saving money but is also ensuring that warehouses can run around the clock, scaling up operations without relying only on human resources.

AI for Logistics and Transportation

Transportation represents one of the most significant supply chain expenses. With rising fuel costs and unpredictable shipping lanes, logistics has become a crucial area for AI integration. AI enables businesses to optimize fleets, reduce idle times, and keep deliveries on track.

AI logistics applications

- Intelligent route planning enhances efficiency by analyzing millions of routes and factoring in traffic, weather, and construction updates. This results in faster shipments and higher fuel efficiency.

- AI-powered fleet management systems reduce downtime by monitoring vehicle health, scheduling timely maintenance, and predicting breakdowns before they occur. This keeps delivery promises intact while cutting repair costs.

- Cargo load optimization maximizes usage by determining the best way to utilize container or truck space. This lets companies ship more goods in fewer trips, reducing overall shipping costs.

- Dynamic delivery scheduling improves last-mile delivery by prioritizing urgent orders, adjusting in real-time to traffic delays, and reducing failed delivery attempts. This directly lowers operational expenses and improves customer satisfaction.

Why it matters: The cost of getting goods from one place to another is rising sharply. By applying AI to transportation, US businesses are able to streamline routes, reduce energy use, and increase on-time deliveries, all contributing to significant cost reductions.

Why Portfolios Matter in an AI-Driven Supply Chain Career

As AI adoption grows quickly in supply chain jobs, professionals who can demonstrate actual projects in automation, forecasting, or logistics optimization will stand out. That is where platforms like Fueler become crucial, helping you build a portfolio of work samples that prove your expertise. Instead of just claiming skills, you can showcase how you built a demand forecast model, improved warehouse efficiency, or optimized delivery routes with AI. Employers prefer professionals who can show tangible outcomes, not just resumes filled with buzzwords.

Final Thoughts

Artificial Intelligence is rewriting the rules of how supply chains operate in the United States. From accurate demand planning to smart warehouse automation and optimized logistics, AI is addressing cost leaks that companies previously considered inevitable. Those who adopt AI early are already seeing savings pile up, while late adopters risk falling behind in efficiency. For professionals, this shift opens opportunities to develop highly in-demand skills and present them in portfolios that build trust.

FAQs

1. How is AI reducing supply chain costs in 2025?

AI cuts costs by improving demand forecasting, automating warehouses, optimizing delivery routes, and reducing equipment downtime with predictive maintenance.

2. Which are the best AI tools for supply chain management in the US?

Blue Yonder, o9 Solutions, Forecast Pro, and Amazon Forecast are some of the most widely used tools by American companies.

3. Can AI completely replace human workers in supply chains?

No, AI is not meant to replace humans completely. Instead, it works alongside workers, reducing repetitive tasks and enabling people to focus on more strategic decision-making.

4. How can small businesses use AI in supply chain operations?

Small businesses can begin by using affordable, cloud-based forecasting tools like Amazon Forecast or integrating AI-driven logistics platforms to improve delivery efficiency.

5. What skills are needed to work in AI-driven supply chains?

Professionals should focus on data analysis, predictive modeling, logistics management, and AI tool usage, while building portfolios to showcase projects in these domains.

What is Fueler Portfolio?

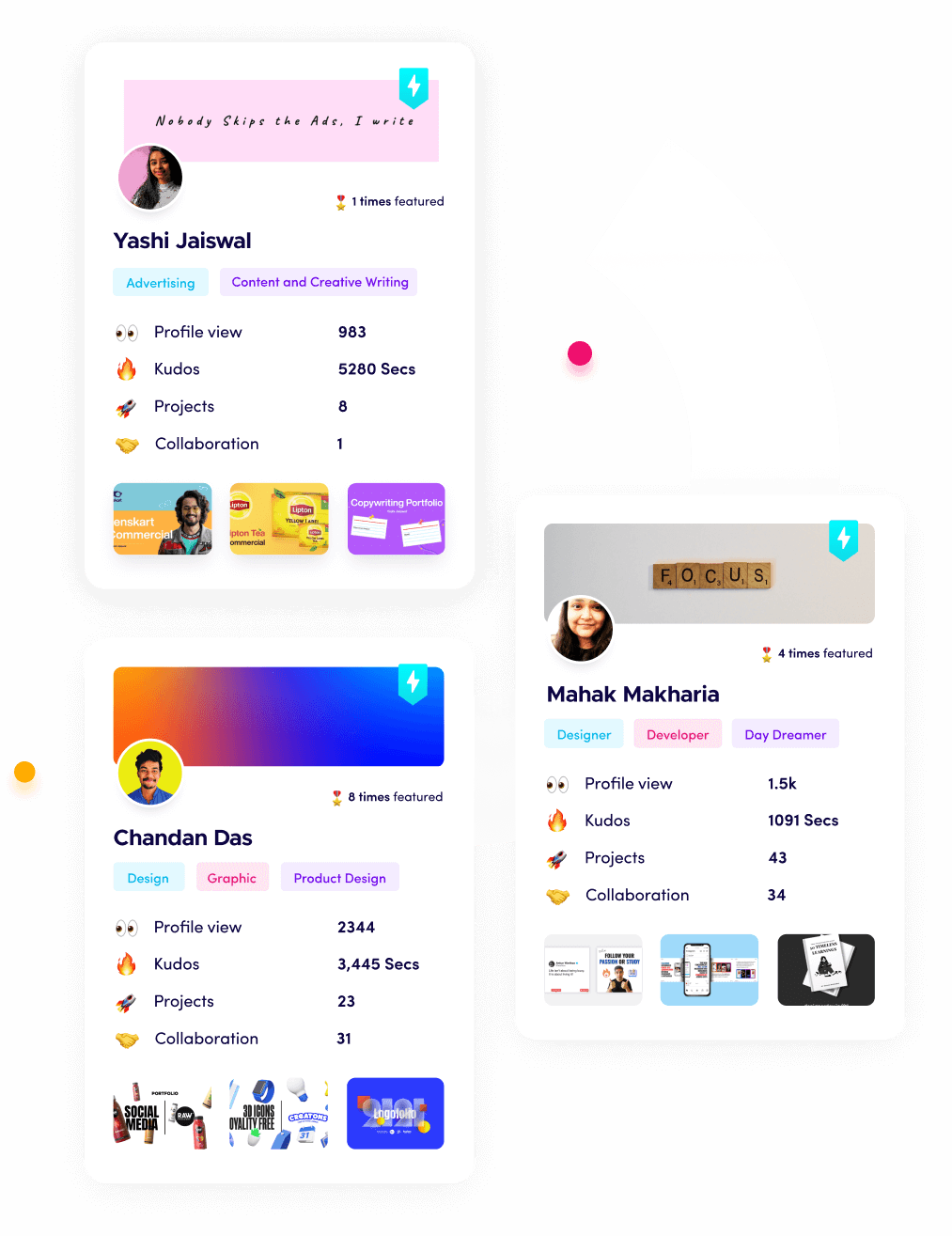

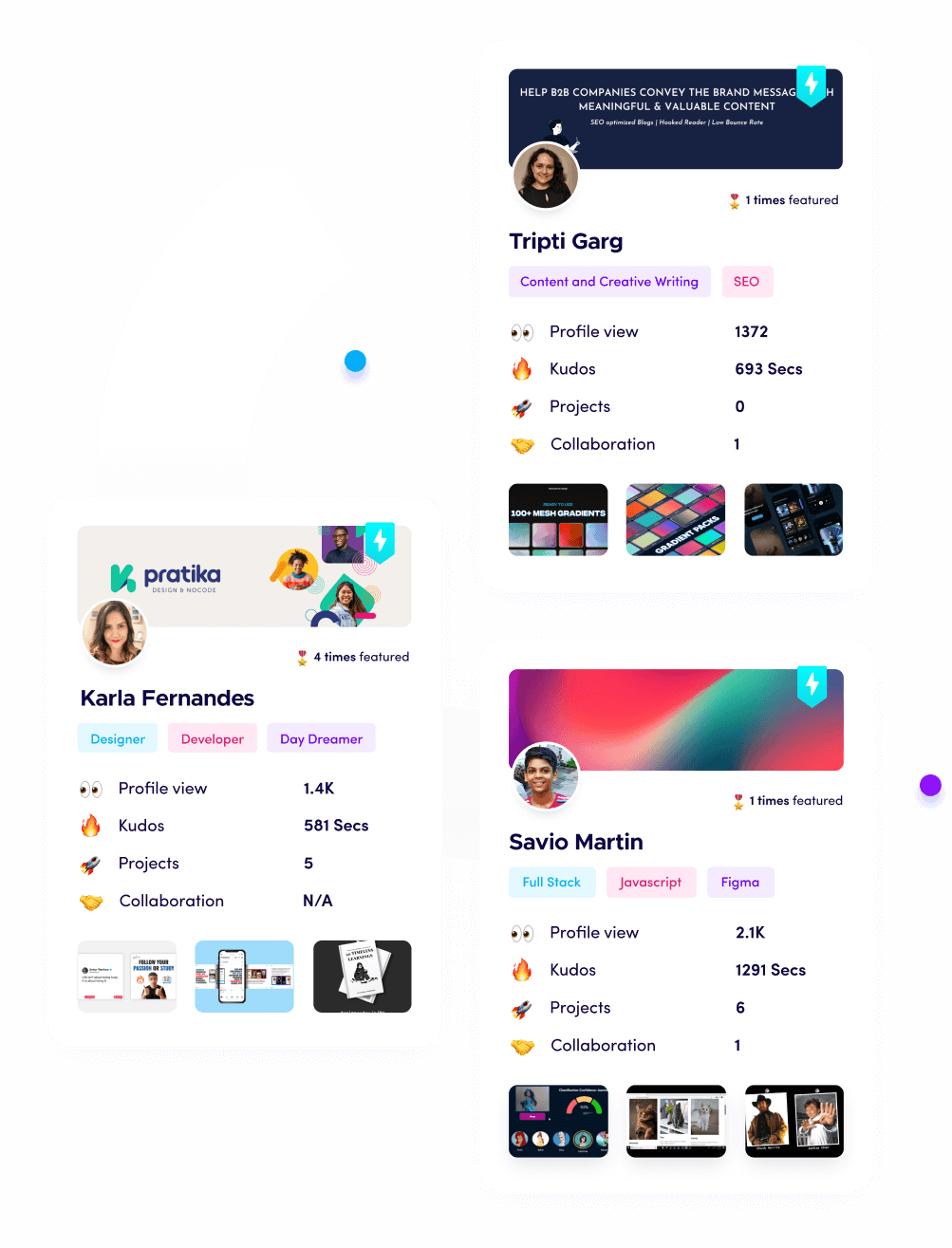

Fueler is a career portfolio platform that helps companies find the best talents for their organization based on their proof of work.

You can create your portfolio on Fueler, thousands of freelancers around the world use Fueler to create their professional-looking portfolios and become financially independent. Discover inspiration for your portfolio

Sign up for free on Fueler or get in touch to learn more.