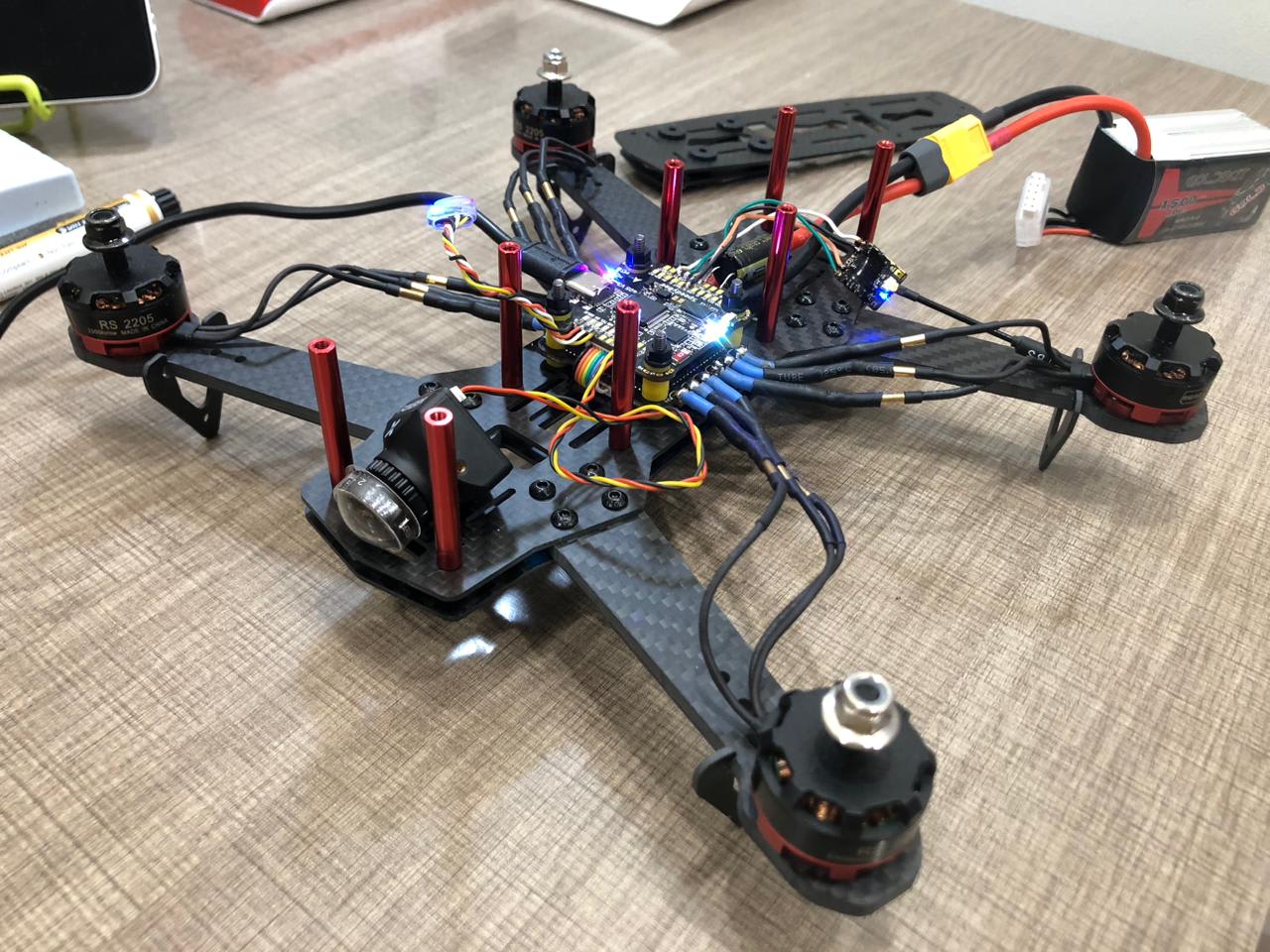

Self Made Drone R&D for newagewear

Case Study: Building India’s Own High-Performance Drone

📌 Context & Background

At Newagewear Distributors LLP, we embarked on a mission to design and build a fully functional, high-performance quadcopter drone that is 90% Made in India. The vision was twofold:

Reduce dependency on imported drone parts and build indigenous capability.

Create a scalable drone product line that could be used across industries — from agriculture and surveying to logistics and defense applications.

As a Product Manager, I drove this R&D initiative end-to-end, ensuring alignment between engineering feasibility, business goals, and go-to-market readiness.

🎯 Problem Statement

Most drones in India were either:

Imported as complete units (with limited customization)

Or assembled using mostly foreign parts, making them costly and less scalable.

👉 The challenge was to develop an India-first drone that maintained performance and affordability, while ensuring local sourcing of components to support self-reliance.

🔑 My Role as a Product Manager

Market & User Research: Identified target use cases (agri-drone spraying, defense surveillance, industrial inspection).

Vendor Development: Sourced ~90% of parts (motors, frames, wiring, PCBs) from Indian suppliers. Only imported critical parts like specific sensors & LiPo batteries.

Product Roadmap: Defined milestones → prototype → testing → iteration → pre-launch.

Cross-functional Collaboration: Worked closely with hardware engineers, software developers, and supply chain teams.

Go-to-Market Preparation: Outlined initial pricing models, B2B pilots, and regulatory pathways (DGCA compliance).

⚙️ Technical Breakdown

Even though my role wasn’t about assembling, I ensured technical feasibility matched product requirements.

Frame: Carbon-fiber X-frame, lightweight yet durable.

Motors: RS2205 brushless motors – sourced from Indian manufacturers.

Flight Controller: F4 series board with custom firmware tuning.

ESCs: 30A BLHeli ESCs – optimized for fast throttle response.

Power Source: 4S LiPo battery (imported due to safety & certification constraints).

Camera Module: FPV-ready, supporting both manual & semi-autonomous navigation.

Wiring & Assembly: All handcrafted and assembled in India.

Outcome: A working drone prototype that achieved stable flight, real-time video feed, and payload capacity testing.

🛠️ Execution Process

Research & Vendor Mapping

Identified Indian suppliers capable of meeting aerospace-grade standards.

Built partnerships for motors, frames, and wiring harnesses.

Prototype Assembly & Testing

Coordinated with engineering to validate design.

Conducted test flights to benchmark stability, speed, and endurance.

Iteration & Optimization

Reduced weight by optimizing frame design.

Improved battery life via ESC calibration.

Pre-launch Preparation

Positioned product as “India’s First Affordable High-Performance Drone”.

Worked on compliance roadmap for DGCA regulations.

📊 Outcomes & Impact

✅ Successfully built a 100% working drone prototype with 90% Indian components.

✅ Reduced import dependency by ~70% compared to standard market drones.

✅ Achieved stable flight testing with payload capacity validation.

✅ Positioned the startup for investor discussions & B2B pilots.

✅ Created a scalable roadmap for future drones in agri-tech, logistics, and surveillance.

💡 Key Learnings as a Product Manager

Hardware + Software Product Management requires balancing engineering depth with business strategy.

Vendor ecosystem building is crucial when innovating in a market dependent on imports.

Iterative prototyping helps bridge the gap between R&D and market-ready product.

The Made in India positioning created strong narrative value for investors and partners.

🚀 Closing Note

This project helped me evolve as a hardware product manager — driving the end-to-end lifecycle from vision to working prototype, while keeping an eye on scalability, market-fit, and business outcomes.

Although I exited before the commercial launch, this R&D initiative laid the foundation for a sustainable, India-first drone product line.

21 Sep 2024